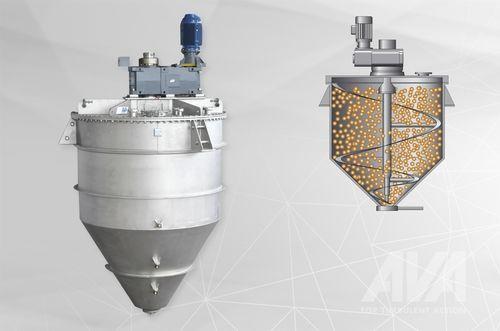

rotor-stator mixer / batch / solid/liquid / vacuum

rotor-stator mixer / batch / solid/liquid / vacuum

100 - 15 000 L | LDSH

INO Group

-

Type:

rotor-stator

-

Batch/continuous:

batch

-

Applications:

solid/liquid

-

Other characteristics:

vacuum

-

Associated function:

with heat exchanger

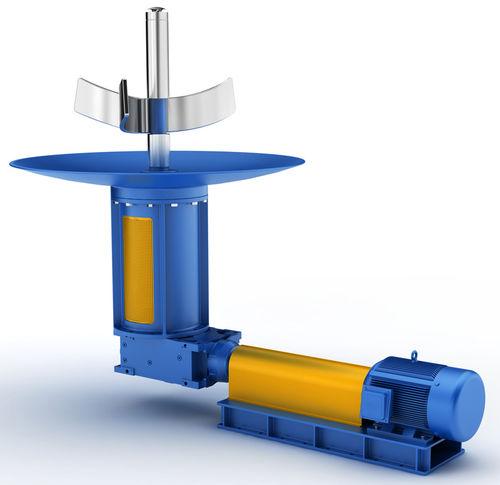

Barrel Agitator Station

Moisture and Bubbles in Large Drums no longer an issue

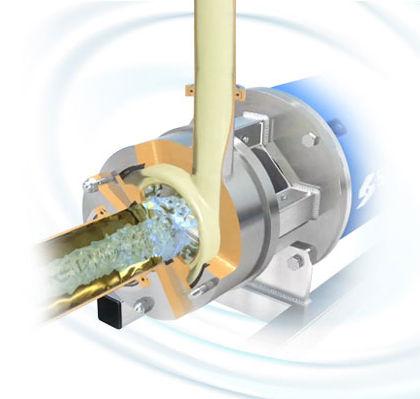

Barrel agitator stations are used in applications with a high material consumption and in combination

with the material preparation and feeding system A310 ensure a homogenous dispensing

material with the right temperature. The electrically powered agitator station is equipped with a

lifting unit, a filling level monitor and an optional vacuum controller and is ideally suited for stirring and

heating liquid dispensing media. The 200 l barrel can be fully evacuated, allowing a comprehensive

preparation of materials that are sensitive to moisture also from large barrels. Loss of material through

damage from moisture in 200 l barrels for example PUR is therefore a thing of the past. The barrel

agitator station, including agitation and filling times, is controlled directly through the A310. Where

several functions are required, the barrel agitator station can also be operated as a stand-alone system

with its own SCP200 controller.

Equipment, depending on model:

SCP200 controller

Vacuum

Lifting unit

Filling-level sensor

Two-hand safety control

Automatic stop of agitator motor

Regulator to infinitely set stirring speed

Mobile collecting tray (200 l)

Inspection glass with lighting